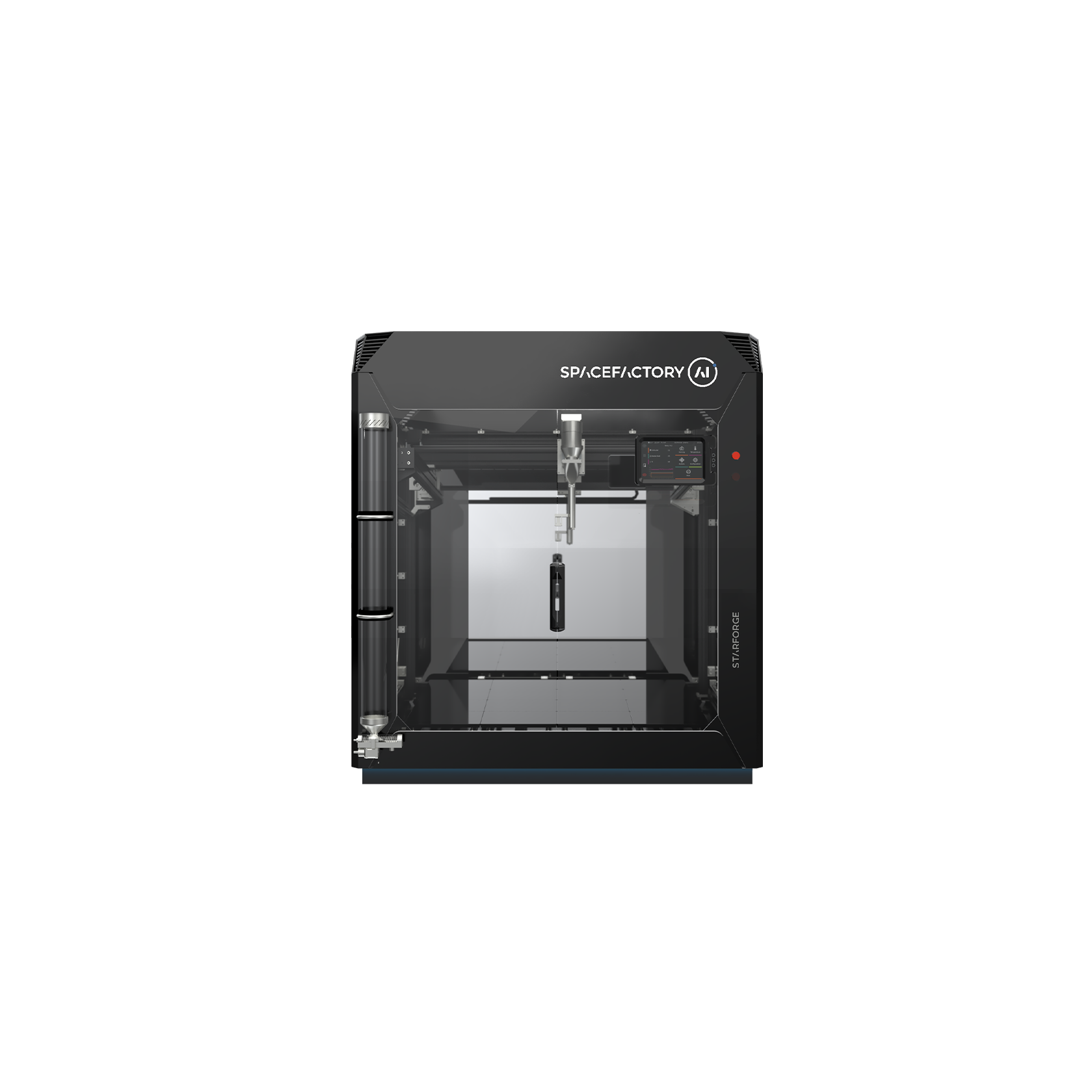

STARFORGE

Large Format 3D Printer

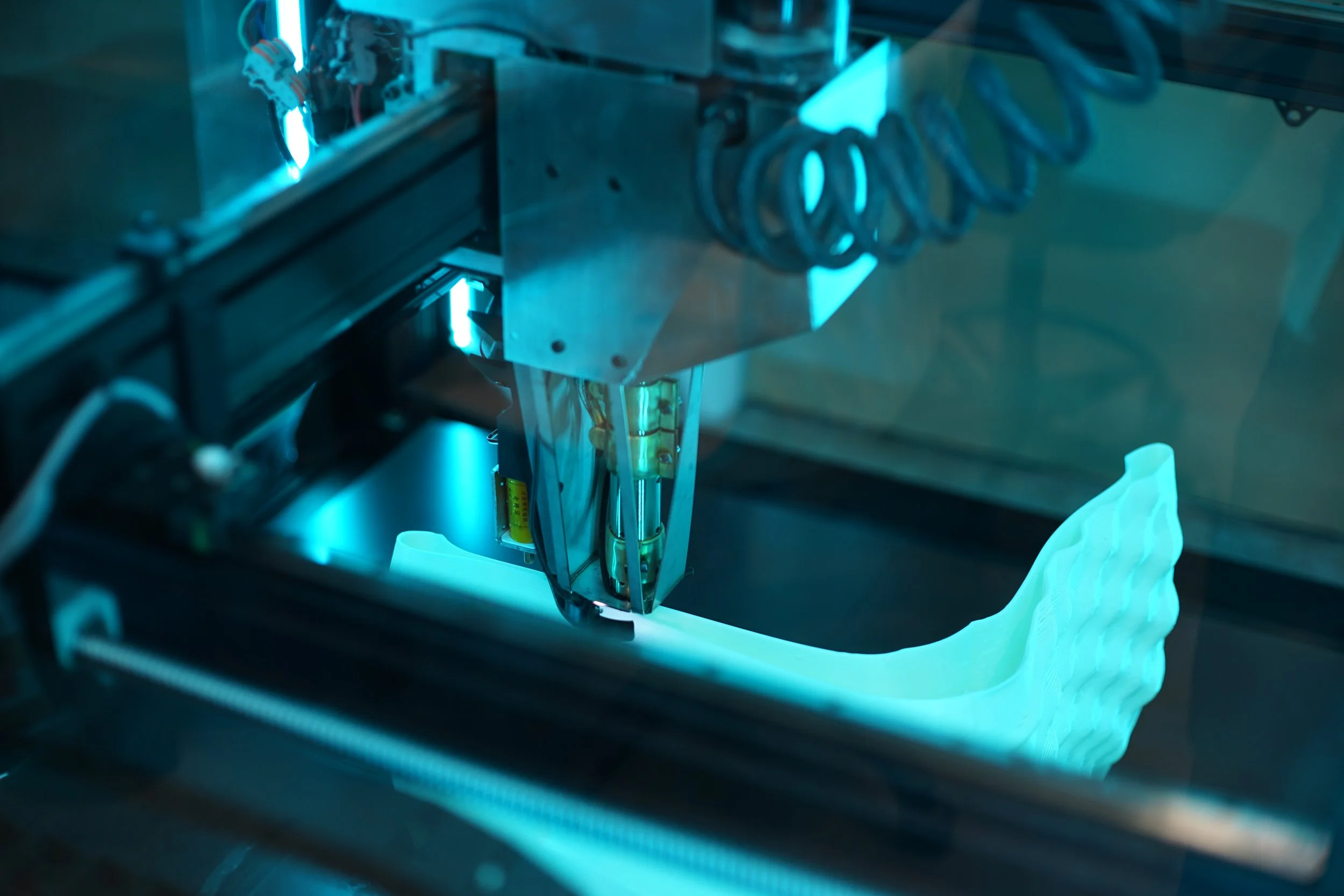

Starforge is a large format 3D printer featuring advanced fused granular fabrication (FGF) technology co-developed by SpaceFactory and NASA for space applications. Compared to filament-based systems, Starforge’s pellet extruder is capable of processing high-fill polymer composite materials including glass, carbon and basalt fibers, and granular materials including lunar simulant. These enhanced capabilities come at a fraction of the cost of comparable high-end FDM/FFF systems, both in materials and machinery.

Effortless Accuracy

0.3% tolerance. Zero complexity.

We designed Starforge ground-up with the goal of “effortless accuracy”, in other words, precision without complexity. Starforge is fully compatible with G-code generated from open-source slicers such as Prusa and Cura, and runs on Klipper firmware. With a huge user community and vast online resources, the transition from desktop 3D printing to operating a Starforge is seamless.

SPECIFICATIONS

Starforge features a highly modular design in basic configurations of tall, long, and cube with a build volume ranging from over 36” up to 100” (950-2600 mm) along any axis. Standard features include a multi-zone heated glass print bed for printing materials up to 300 C.

-

Pellet extruder

Heated glass bed

Auto-quad leveling

Mesh leveling

Vacuum delivery system

Touch screen

-

Build Volume: 1000 mm x 1000 mm x 1600 mm

Overall Dimensions: 1630 mm x 1630 mm x 2460 mm

Weight: 560 kg

Throughput: 3.4 kg/hr (7.5lb/hr)

Print Velocity: 200mm/s

Power: 208V 3-Phase AC 30A

Bed temperature: 100°C (212°F)

Print Temperature: 280°C (536°F)

MODELS

-

T200

Build Envelope - W: 950 L: 1050 H: 1600 (37” x 41” x 63”)

Frame Size - W: 1500 L: 1500 H: 2000 (59” x 59” x 79”)

T250

Build Envelope - W: 950 L: 1050 H: 2100 (37” x 41” x 83”)

Frame Size - W: 1500 L: 1500 H: 2500 (59” x 59” x 98”)

T300

Build Envelope - W: 950 L: 1050 H: 2400 (37” x 41” x 102”)

Frame Size - W: 1500 L: 1500 H: 3000 (59” x 59” x 118”)

-

L200

Build Envelope - W: 950 L: 1550 H: 1100 (37” x 61” x 43”)

Frame Size - W: 1500 L: 2000 H: 1500 (59” x 59” x 59”)

L250

Build Envelope - W: 950 L: 2050 H: 1100 (37” x 81” x 43”)

Frame Size - W: 1500 L: 2500 H: 1500 (59” x 79” x 59”)

L300

Build Envelope - W: 950 L: 2550 H: 1100 (37” x 100” x 43”)

Frame Size - W: 1500 L: 3000 H: 1500 (59” x 118” x 59”)

-

C200

Build Envelope - W: 1450 L: 1550 H: 1600 (57” x 61” x 63”)

Frame Size - W: 2000 L: 2000 H: 2000 (79” x 79” x 79”)

C250

Build Envelope - W: 1950 L: 2050 H: 2100 (77” x 81” x 83”)

Frame Size - W: 2500 L: 2500 H: 2500 (98” x 98” x 98”)

C300

Build Envelope - W: 1950 L: 2050 H: 2600 (77” x 81” x 102”)

Frame Size - W: 3000 L: 3000 H: 3000 (118” x 118” x 118”)

Made in the USA,

from Earth to beyond

Crafted with pride in our Meadowlands facility in New Jersey, every Starforge is a testament to American ingenuity. The “Starforge” story is woven with our collaboration with NASA— a partnership that pushed us to bring space-age solutions down to Earth—including the first ever 3D printer to successfully print in cryogenic vacuum.