ASTRA

Robotic 3D Printer

ASTRA is a full-stack robotic 3D printer engineered for scale and simplicity. We combined industrial robotic performance with state of the art extrusion and material handling technology, recycled 3D print material, and automated code generation. With ASTRA, you’re accessing NASA award-winning technology to build beyond conventional boundaries of material and dimension.

Space-driven

Explore the frontier of making with NASA award winning technology

SCHEMATICS

-

The ABB IRB-6700 is a six axis robotic arm that can handle up to a 245 kg payload and has a 3m reach. Six degrees of motion and extensive reach allow for both an orthogonal and polar build envelope.

-

Fabricated out of welded steel, the boom carries the components of the extrusion system including its controls. It’s unique V-Shape allows for a larger vertical range of motion while minimizing torque exerted on the robot.

-

The extruder is comprised of a hopper system, feed section, barrel, screw, and melt pump, which are powered by two Yaskawa Servo Motors coupled with GAM Gearboxes.

-

The Material Delivery System sends pellets from the material boxes to the extrusion system via hoses connecting each of up to two boxes to a valve and then the hopper system. The material flow is controlled by these valves and a 700AW vacuum.

-

The onboard computer houses the electronic controls for the system and sits in a custom designed box inside the boom. It features two plates through which cables connect to the extruder and dress pack, and includes components like heater controls, power supplies, USB/ethernet ports, and indicator LEDs.

-

While the dress pack also contains electronic controls for the system, it is kept separately from the onboard computer to alleviate the weight on the robot’s primary axis. These controls include the motor drivers and additional power supplies and USB/ethernet ports.

ASTRA ABB IRB-6700 Configuration

SPECIFICATIONS

-

Ortho Setting: 1200 mm x 2400 mm x 1200 mm

Polar Setting: 300° / 3750 mm radius x 3250 mm max ht

-

Throughput: 90 lb/hr

Print Temperature: 175°C – 315°C

Heating : 6 kW 4 zone control

Layer Height : 2 - 7 mm

Line Width : 10 - 35 mm

-

Mobility : 6-axis

Print Velocity : 5 – 200 mm/s

Extruder Motor : 6000 rpm / 3.0 kW

Melt Pump Motor : 2500 rpm / 1.0 kW

Repeatability: 0.05 mm

Accuracy: 0.10 mm

-

Robot: 480V 30A

End Effector: 208V 3-phase: 30A-20A-20A

-

Robot: X: 2560 mm Y: 1009 mm Z: 2321 mm

Robot Mass: 1540 kg

TCP Offset: X: 1152 mm Y: 0 mm Z: 605 mm

End Effector Mass: 132 kg

Barrel Length: 762 mm

Barrel Inner Diameter: 30 mm

Nozzle Diameter: 12 mm

Reach Diagram with ABB-IRB 6700 245/3.0

Earth-minded

Give new dimension to plastic waste

MATERIAL

-

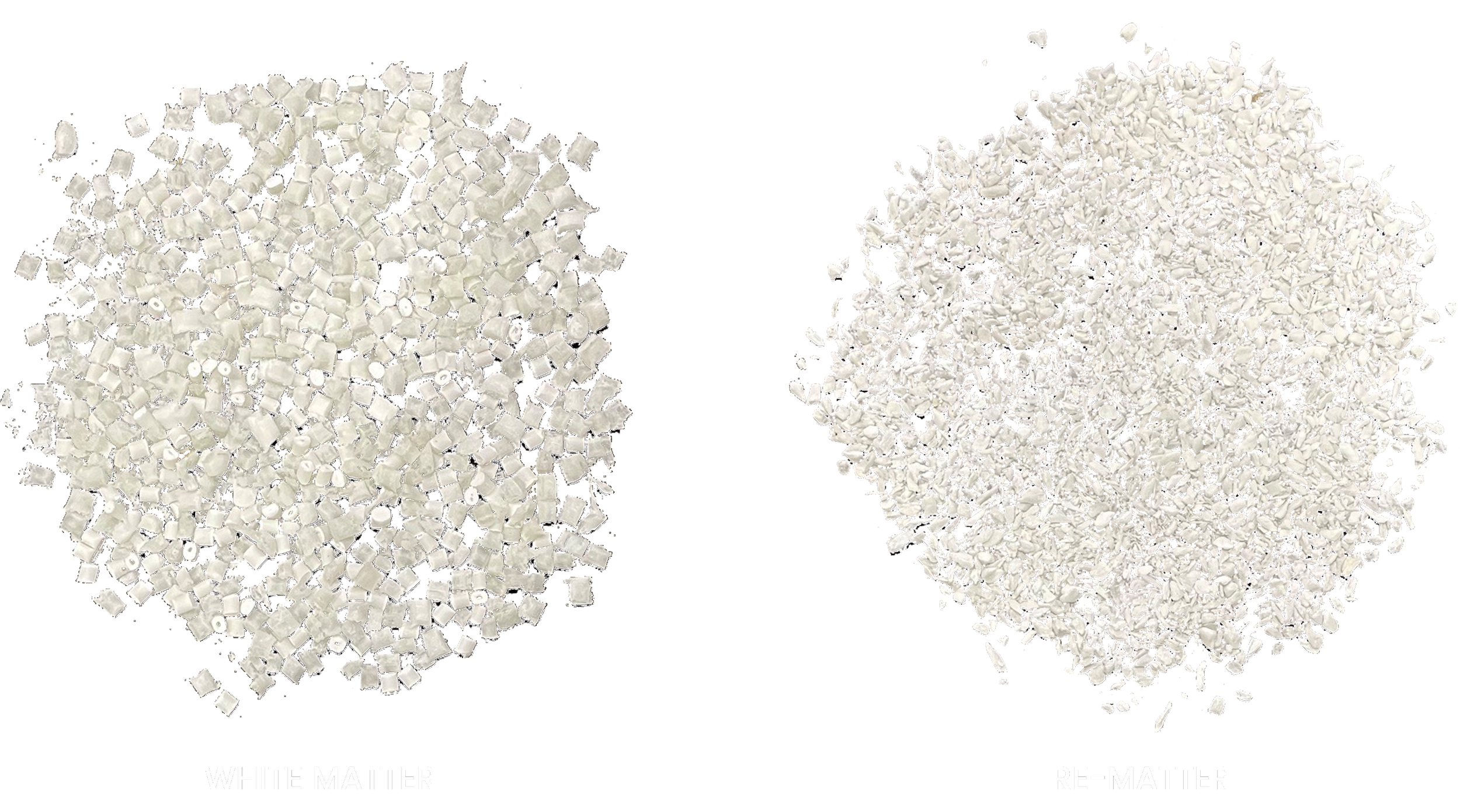

White Matter is our multipurpose material selected for its excellent strength-to-cost ratio and processability.

Estimate Bulk Properties*

Tensile Strength : 40-125 MPa

Compressive Strength : 60-90 MPaDirectional Properties**

Flexural Yield Strength, Planar : 90 MPa

Flexural Yield Strength, Layer-to-Layer : 7.5 MPa

Flexural Moduls : 4.5 GPa*estimated from various sources; targeted testing currently underway

**properties vary depending on print orientation -

Re-matter is, as its name suggests, reground White Matter made from scrapped prints. Over 80% of regrind is recaptured as 3D printable flakes which are compatible with ASTRA’s material handling system.

Our proprietary 3D print materials are 100% post-industrial plastics reinforced with glass fibers. We’ve used this high-strength composite to produce structures which span and support heavy loads. Every 3D printed scrap of material can be recycled and reprinted so that absolutely nothing goes to waste.

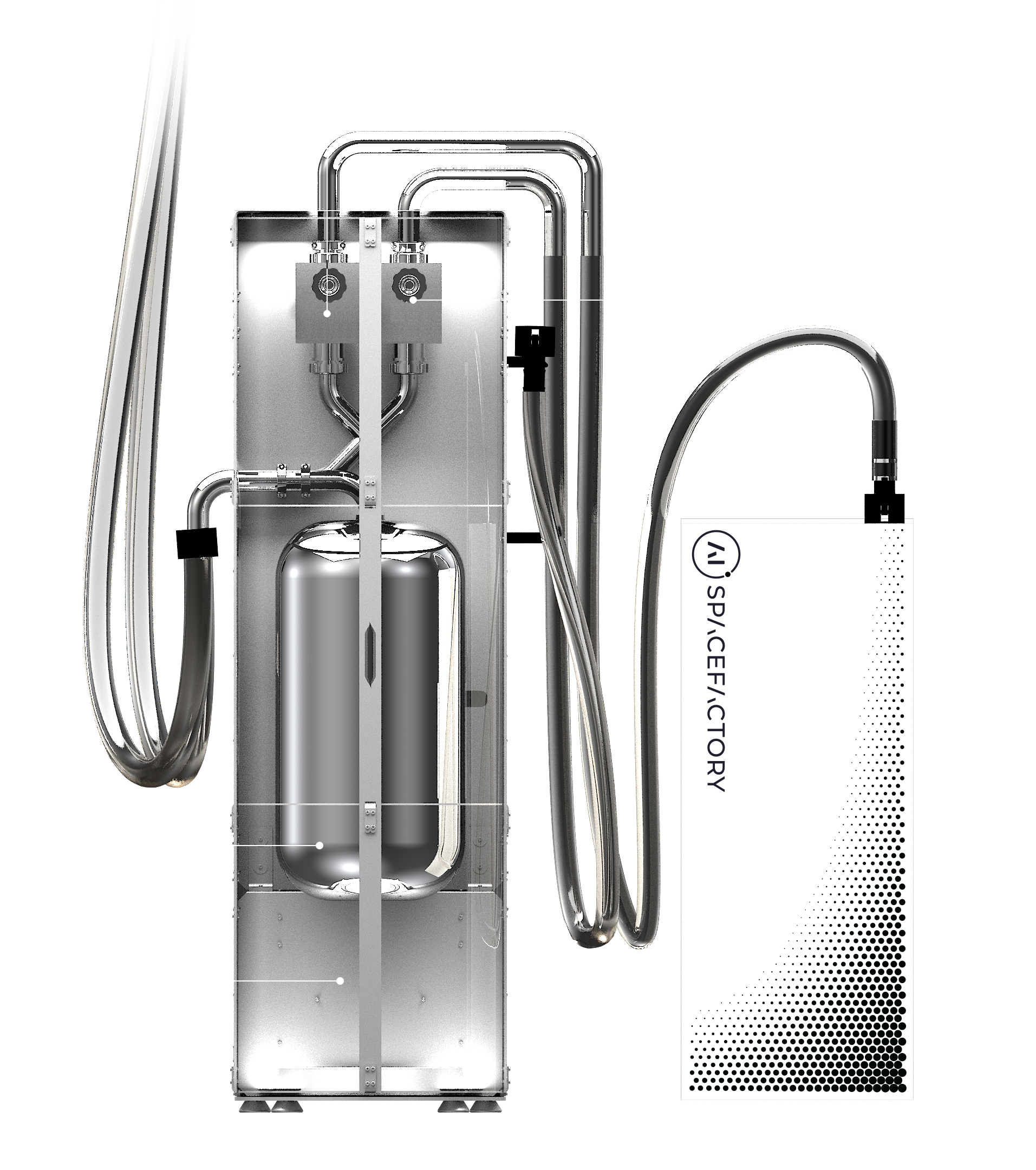

MATERIAL HANDLING

-

The material flow is controlled by a 22 liter, 700AW vacuum. System noise is minimized through an integrated muffler near the motor. The vacuum filter is easily serviced by opening the station doors and dropping the housing onto the lower rest.

-

The two valves in the Material Delivery Station control which box material is pulled from. These electric actuated 2-piece stainless steel ball valves allow the Delivery Station to automatically switch between boxes when necessary to ensure material flow is uninterrupted during a print.

-

Each Delivery Station can connect to two Material Boxes. Each Box has a cam and groove coupling that connects to the Delivery Station’s hoses and an RFID tag that allows the onboard computer to recognize the type of material.

-

The Delivery Station also has its own onboard computer, which contains the electronics necessary to control the vacuum and valves within it. This computer also communicates material information and system status to other subsystems via ethernet.

-

An RFID reader is integrated into the Delivery Station. The reader allows the Delivery Station to recognize new material boxes, confirm the material they contain, and adjust print parameters accordingly.

ABB-ARB 6700

User-centric

Plug-and-play, so you can print the future

SOFTWARE

-

Start by loading ASTRA’s print profile, then prepare prints with a few clicks or dive into custom settings for in-depth control.

-

Convert G-Code to Rapid Code with a simple drag-and-drop. Features: CSV file consumption for processing target coordinates generated by Grasshopper, Excel, or custom script. Built-in JSON editor for customizing Ropedancer settings. Polar-mode option for printing outside the standard build envelope.

-

The world’s most used offline programming tool for robotics, ABB’s simulation and offline programming software, RobotStudio is built on the ABB Virtual Controller, an exact copy of the real software that runs your robots in production. This allows for high fidelity simulations, using real robot programs and configuration files identical to those used on the shop floor.

-

Our proprietary onboard operating system, PHOBOS controls every aspect of ASTRA’s function, from commanding motors to regulating temperatures. PHOBOS communicates with the ABB robot controller to synchronize movements and monitor status while 3D printing.

We designed ASTRA to be as streamlined as using a desktop 3D printer. Slice your 3D model in Cura and drag-and-drop into our software to generate a ready-to-use program. While 3D printing, ASTRA’s onboard operating system will regulate the entire process to achieve the smoothest print possible.