MARSHA

BUILDING A MARS HABITAT

ARCHITECTURE ON MARS

In an alien environment 54.6 million kilometers away, construction and materials must be rethought entirely.

Architecture on Earth plays a critical role in the way we live. On Mars, this reaches a higher level of importance since buildings are also machines we depend on to keep us alive and well. In Space architecture, every design decision is of great consequence to the success of a mission. Structures must be resilient and interior layouts must be tuned to mission demands. And yet, since sustained social and mental health are also mission-critical, Space habitats must be designed to be rich, useful, and interesting worlds onto themselves. Marsha, AI SpaceFactory’s Mars habitat design, illustrates that the result can be both visionary and credible with an alien yet familiar beauty.

3D PRINTING

IN-SITU RESOURCE UTILIZATION

Martian exploration and settlement at any meaningful and sustainable scale will depend on the utilization of materials found on Mars. This is enabled by in-situ resource utilization (ISRU) technologies. ISRU circumvents the hard limits of the rocket equation wherein every 10 pounds of rocket needs roughly 90 pounds of propellant. Without ISRU, the cost of importing materials from Earth renders the project of extraterrestrial futures impossible.

To get around this, Space agencies and companies plan to send machines in advance of human crews to harvest the raw Martian materials and process them into forms that can be deposited and assembled into homes and other structures. Thus, using technologies tested on Earth first, our future Mars habitats can be built ahead of our arrival.

IMPROVED STRUCTURE

MARSHA is a first principles rethinking of what a Martian habitat could be – not another low-lying dome or confined, half-buried structure, but a bright, multi-level, corridor-free home that stands upright on the surface of Mars. Where structures on Earth are designed primarily for gravity and wind, Martian conditions require a structure optimized to handle internal atmospheric pressure and thermal stresses. Marsha's unique vertically oriented, egg-like shape maintains a small footprint, minimizing mechanical stresses at the base and top which increase with diameter. Standing tall on the surface grants the human crew a superior vantage point to observe a dynamic landscape with weather patterns, clouds, and shifting hues – their new home and object of study. The tall, narrow structure reduces the need for a construction machine to continuously rove on the surface, reducing risk and increasing speed and accuracy.

These innovations challenge the conventional image of “space age” domes by focusing on the creation of spaces tuned to both known and anticipated physical and psychological demands of a Mars mission.

DUAL SHELL

MARSHA employs a unique dual-shell scheme to isolate the habitable spaces from the structural stresses brought on by Mars’s extreme temperature swings. This separation makes the interior environment unbeholden to the conservativism required of the outer shell, which retains its simple and effective form. As a result, the interior is free to be designed in the sense we take for granted on Earth – around human needs.

OPTIMIZED CREW HEALTH

EARTHLY CONDITIONS FOR CREW HEALTH AND PERFORMANCE

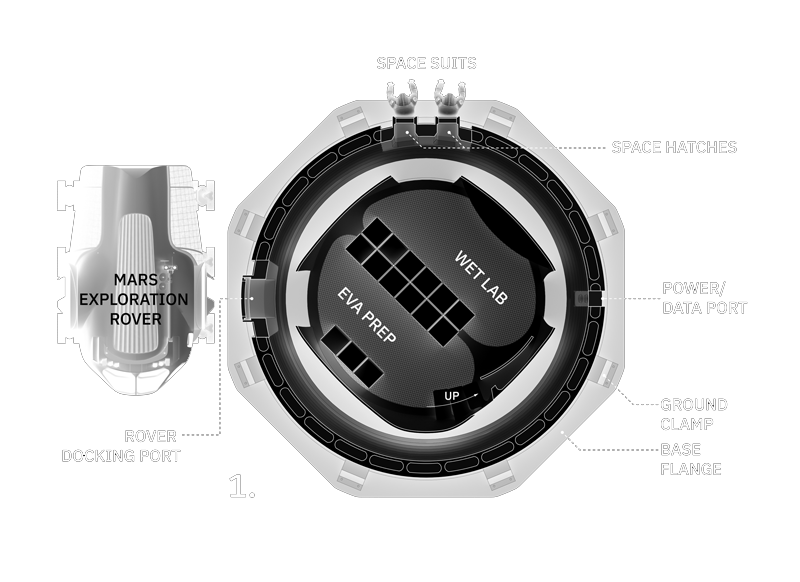

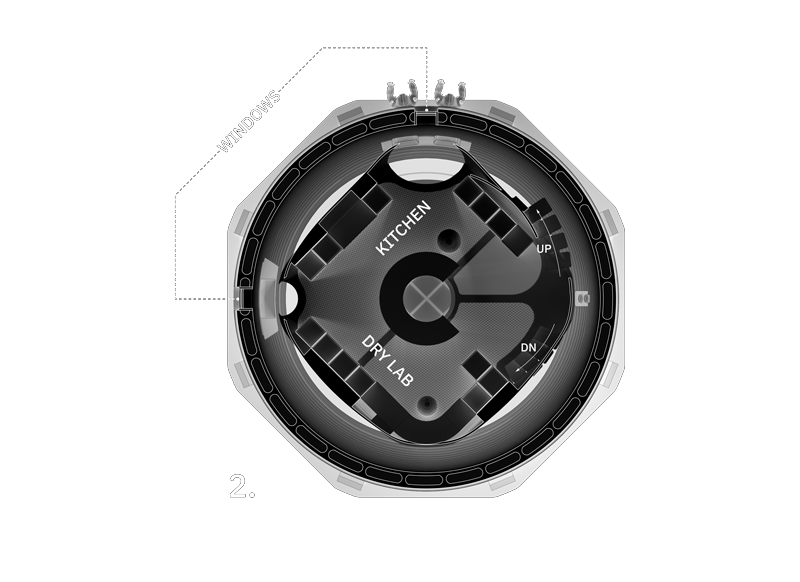

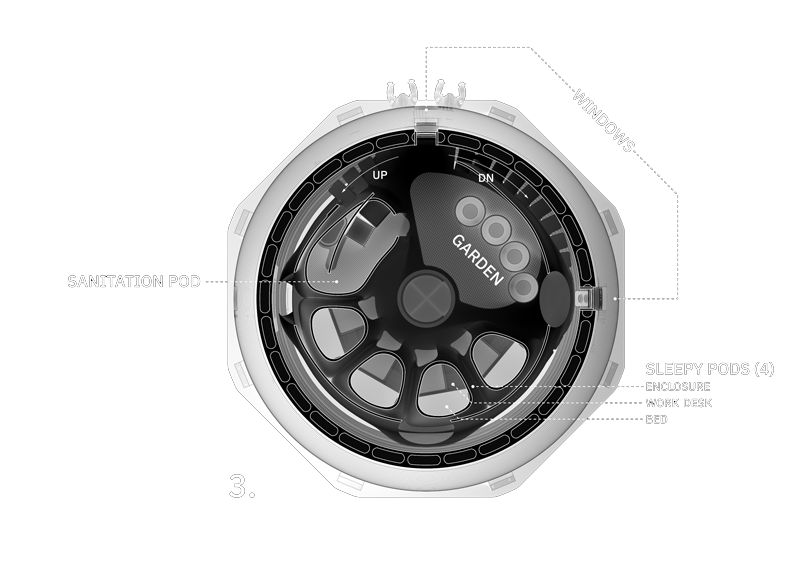

MARSHA's functional areas are spread over four levels identified by a unique interior atmosphere that encourages mobility and averts monotony. Via the large skylight above and intermittent windows, the space between the two shells acts as light-well connecting all levels with diffuse natural light. This unique space allows for a stair to arc gently from floor to floor, adding dimension to daily life.

Missions present stresses and challenges that must be addressed spatially, reflecting the strict flow of tasks typical of space missions. But since sustained social and mental health are also mission critical, MARSHA offers elements of surprise and literal room for the crew to slip outside of an overly prescriptive existence. MARSHA's layout is zoned with both of these principles in mind.

Each level has at least one window, which together cover the full 360 degree panorama. Indirect natural light from the large water-filled skylight and intermittent windows floods the interior while still keeping the crew safe from harmful solar and cosmic radiation. Circadian lighting, designed to recreate Earthly light, is employed to maximize crew health.

INNOVATIVE CONSTRUCTION MATERIALS

OUR FORMULA FOR 3D PRINTING ON MARS

In collaboration with Techmer PM, we've formulated an innovative mixture of basalt fiber extracted from Martian rock and renewable bioplastic (polylactic acid, or PLA) processed from plants grown on Mars. This recyclable polymer composite outperformed concrete in NASA’s strength, durability, and crush testing. ASTM lab tested and certified to be two to three times stronger than concrete in compression, our space-grade material is also five times more durable than concrete in freeze-thaw conditions.