LINA

BUILDING ON THE MOON

Within the next decade, the Artemis Mission will send astronauts to the Lunar South Pole, a region described as “The Peak of Eternal Light,” where the sun is omnipresent and resides at a low angle of incidence. This site is likely to be near a crater rim that yields long duration illumination for solar power collection and in proximity to permanently shadowed crater regions, which are of interest for water harvesting operations.

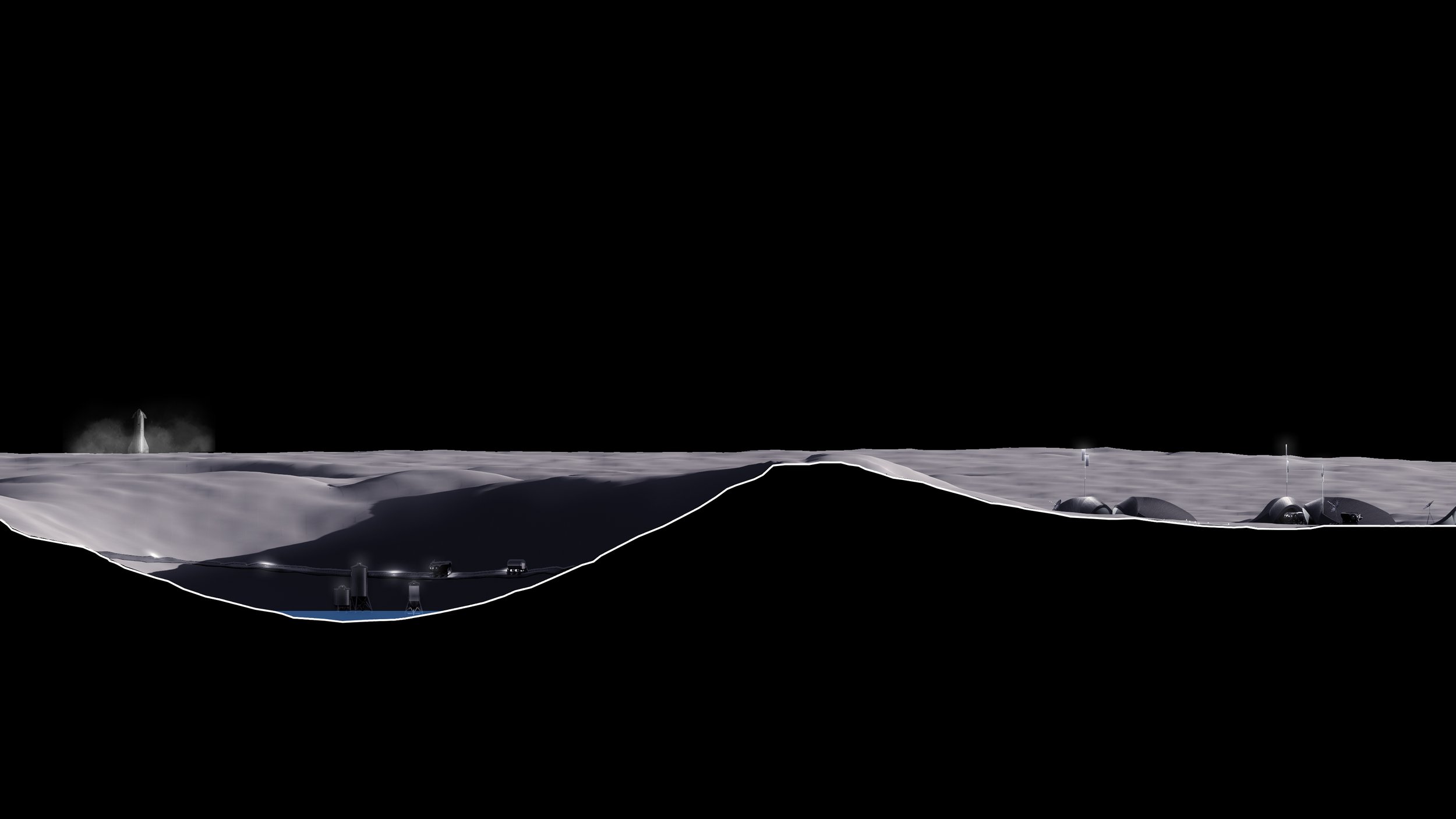

Unlike conventional 3D prints, where layers are parallel to the ground, LINA will be 3D printed at a 60-degree angle to construct the continuous, vaulted roof. A regolith berm, prepared in advance, functions as an inclined print bed to support the initial layers. To prevent warping as the material cools, and to improve adhesion of the 3D print material to the regolith print bed, reusable metal tiebacks will be inserted into the berm to anchor the first layers. As the roof begins to take shape, a mobile excavator will follow behind the 3D print head to cover LINA with a protective regolith overburden. Finally, the regolith overburden is shaped to give LINA a sleek, yet symbiotic form designed to meld into the lunar landscape.

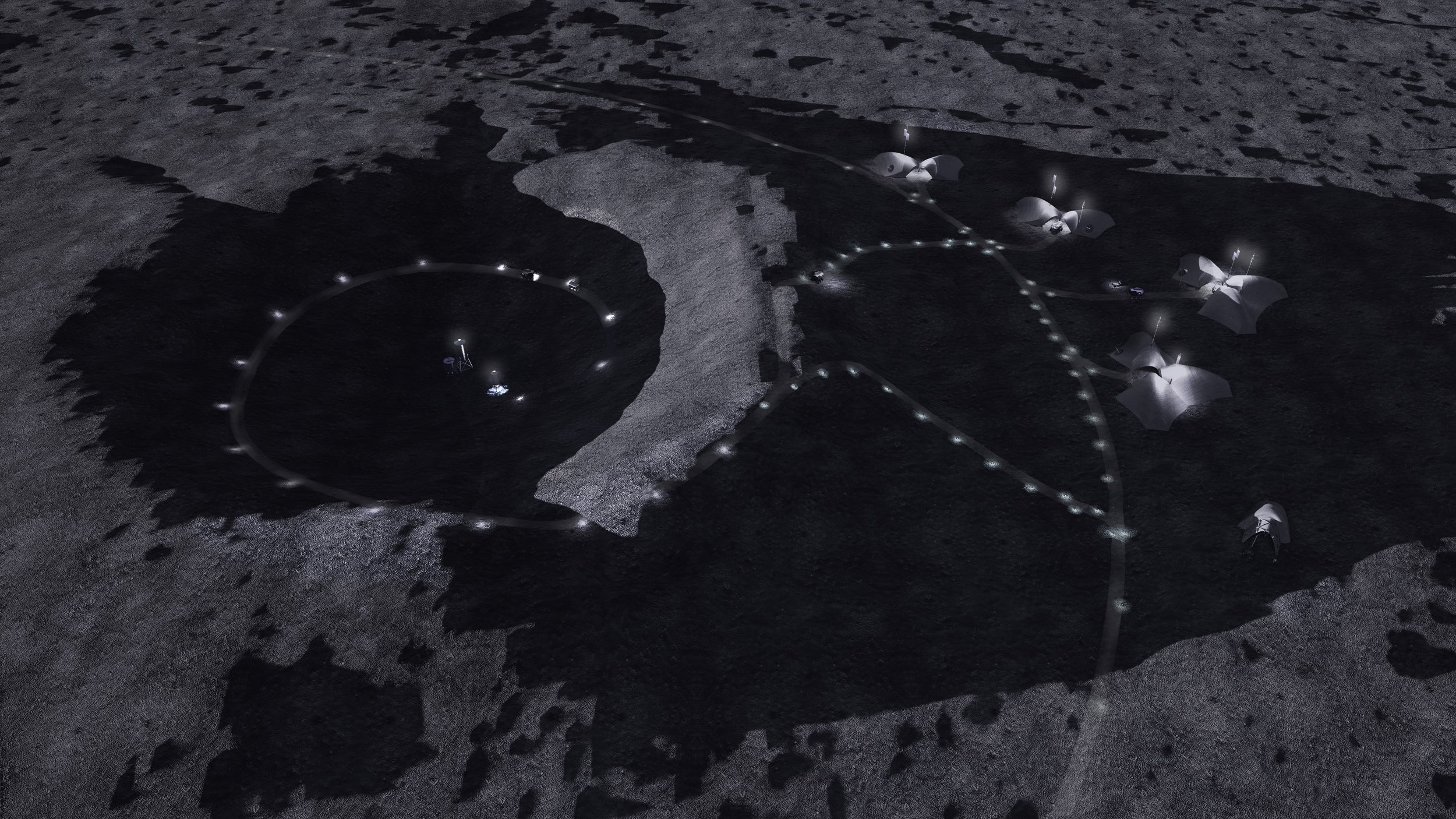

LINA is a humble yet strategic approach that is evocative and adaptive to the native terrain of the moon. Unlike MARSHA, our Mars surface habitat which was designed as a free-standing object, LINA is extensible from a single structure to a cluster of units that become a larger and more systemic lunar outpost. The orientation of LINA provides self-shading, thereby leveraging topographical features in the lunar landscape to shield from lethal solar and cosmic radiation.

LINA is our design of a Lunar outpost which is both adaptive and visually sensitive to the Lunar environment. As we realize this long-lived imagination of expanding civilization to Earth’s one and only natural satellite, we are also mindful of exploring the moon in a sustainable way that minimizes human disturbance. To achieve this goal, SpaceFactory - in partnership with NASA - is developing technologies for in-situ lunar surface construction within the timeframe of the Artemis Mission: humankind’s return to the Moon.

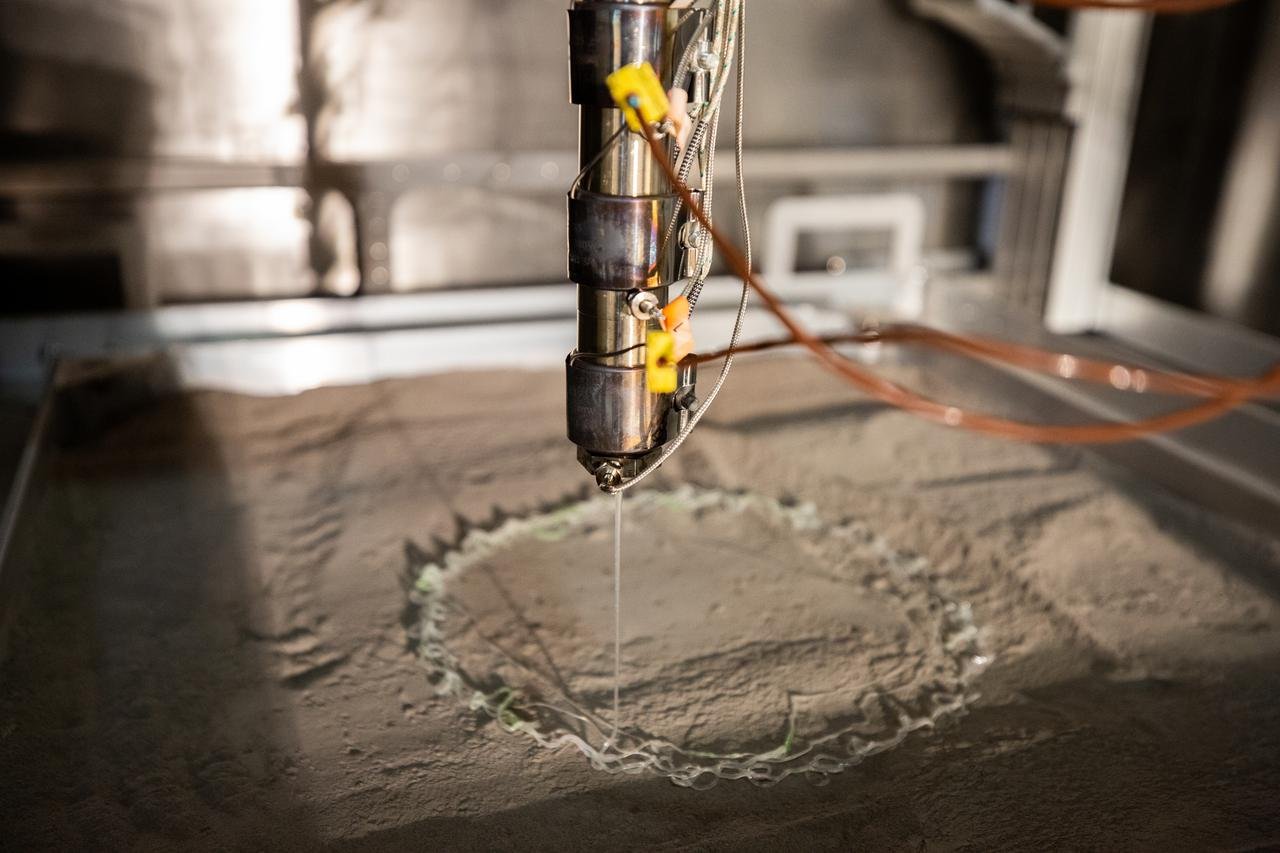

To construct LINA, SpaceFactory is advancing the development of a Space-rated 3D printing system designed to operate in vacuum with temperatures ranging from -170º to 70ºC. The first such prototype, built by SpaceFactory together with NASA, is undergoing testing at Kennedy Space Center in a lunar environmental chamber designed to mimic the exact conditions at the Lunar south pole. The 3D print material, formulated by SpaceFactory from BP-1 lunar simulant, was synthesized by NASA’s Granular Mechanics and Regolith Operations Lab and subsequently validated in static extrusion tests performed in vacuum.

Designed with a life expectancy of at least 50 years, LINA’s primary function is to protect astronauts and critical mission assets against hazards such as galactic cosmic radiation exposure, solar particle events, moonquakes, micrometeoroid impacts, lunar dust contamination, and cryogenic conditions experienced during the lunar night. LINA’s ultra-thin shell is designed to support a 2.7-meter thick protective regolith overburden. The result is a lightweight, mass optimized structure that functions as defense against radiation and the extreme lunar environment.

LINA is sized to shelter a pressurized, manned rover such as the Space Exploration Vehicle, telecommunication devices, and habitation modules. The design of the structure incorporates three separate units that share a communal courtyard and integrate a photovoltaic tree to directly capture and harvest solar energy. The occupiable floor area of each unit is 75 square meters, the central staging area is 90 square meters, and the 3D printed shell has dimensions of 8 meters by 9.4 meters with a height clearance of 5 meters.

LINA will be 3D printed with a high-performance mixture of native lunar regolith and Earth-sourced polymer binder. To minimize the polymer mass imported from Earth, we studied numerous configurations from thick to thin shells, adopting a parabolic cross section so that the loads will always be in compression. Ultimately, we found that a thin shell with a diagonal brace rib had the most efficient ratio between weight and load carrying capacity. This specific geometry is inscribed by a 5-meter diameter circle to match a large rocket fairing, meeting the ground at a 70-degree angle to maximize internal space.

As we broaden the horizon of what is possible in the future, LINA is an architectural and technological milestone that sets precedent for the pursuit of explorations more distant than our moon.

Below, NASA test prints LINA in vacuum.