ADVANCED MANUFACTURING

FOR EARTH AND BEYOND

SpaceFactory is a NASA award winning company developing advanced manufacturing technologies for Space exploration with far-reaching terrestrial applications.

STARFORGE

INTRODUCING OUR NEWEST LARGE FORMAT 3D PRINTER

MADE IN THE CITY

HOW 3D PRINTING COULD BRING MANUFACTURING BACK TO THE AMERICAN CITY

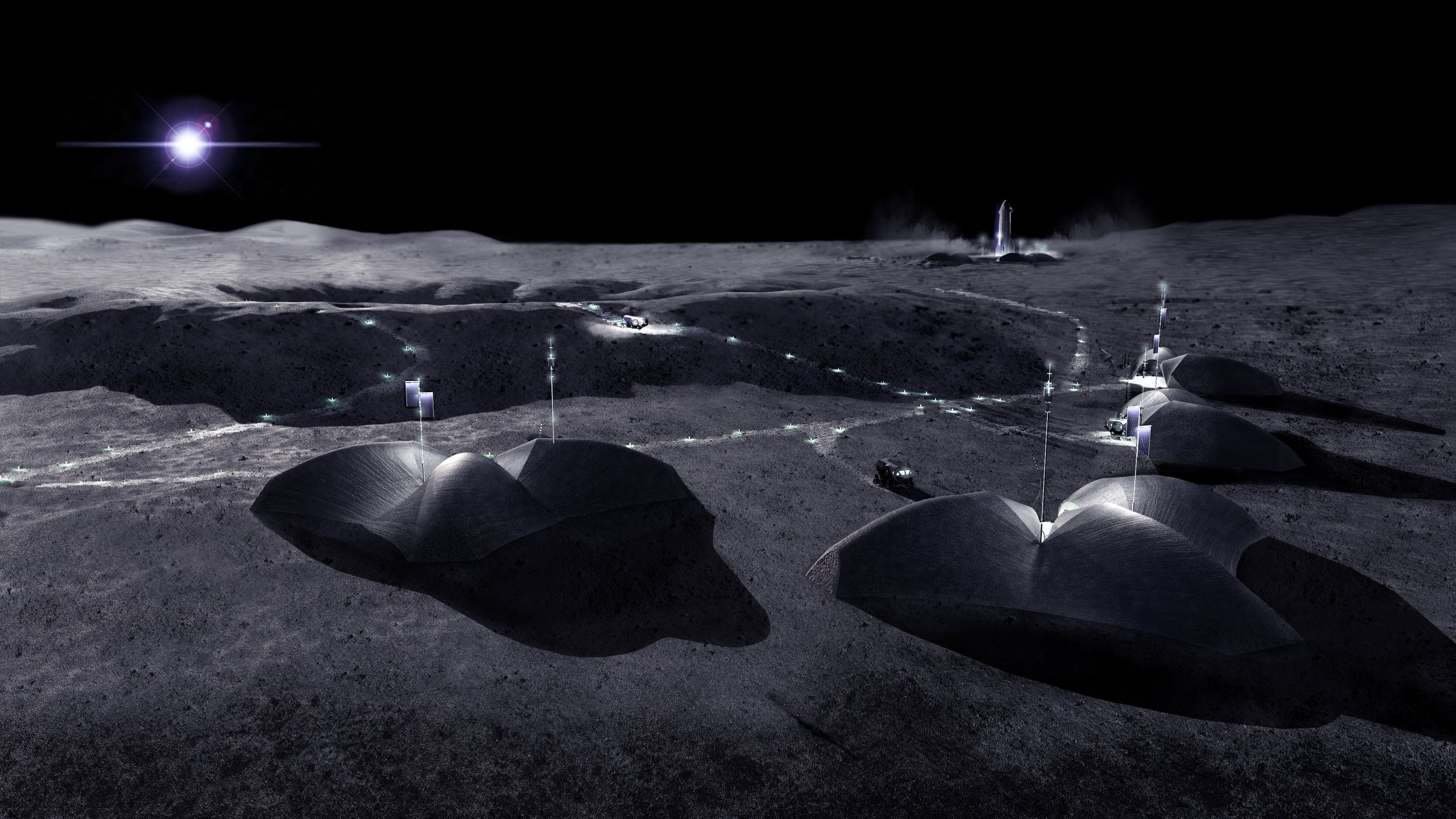

BUILDING ON THE MOON

LINA

OUR MISSION

Our mission is to be the first builders on the Moon and beyond, laying the foundations of humanity’s future in Space and harnessing those discoveries into an era of sustainable construction on Earth.

TIMELINE

-

AI SpaceFactory was founded in February 2017 by a team of architect and engineers to enable human habitation beyond Earth, and to apply those technologies to improve how we build and live on our planet. That same year, we embarked on the multi-phase NASA Centennial Challenge to develop the design and technologies to build on Mars—a challenge we ultimately won in May 2019.

-

AI SpaceFactory entered NASA's 3D Printed Habitat Challenge in its third and final phase which required the design and construction of a prototype Martian habitat. Through the challenge, we began to push the thresholds of what's possible within 3D printing technology and materials.

NASA CENTENNIAL CHALLENGE - DESIGN PHASE 2ND PLACE WINNER

SpaceFactory was one of five designs selected from a field of seventeen teams due to our innovative design born from the Martian environment. Our Mars habitat, MARSHA, marks a radical departure from previous habitat designs. MARSHA stands upright and tall on the Martian surface with highly human-centric, habitable spaces tuned to the demands of a Mars mission.

NASA CENTENNIAL CHALLENGE - 1ST PLACE WINNER

AI SpaceFactory was announced the ultimate winner of the NASA 3D Printed Habitat Challenge, receiving a $500K award to seed future research and development. Our 15-foot tall prototype was commended for its high degree of autonomy and use of a recyclable biopolymer 3D print material that withstood NASA’s pressure, smoke, and impact tests better than its concrete competitors.

-

AI SpaceFactory began the TERA (short for Terrestrial Analog) project to validate our space-technologies on Earth. An eco-friendly 3D printed dwelling made entirely with sustainable materials, TERA proves that revolutions in technology, artificial intelligence, and robotics can reduce waste and our collective carbon footprint through Space-driven construction.

-

SpaceFactory is one of 17 companies selected by NASA to co-develop lunar technologies under the Announcement of Collaboration Opportunity (ACO) program alongside Blue Origin and SpaceX.

The partnership between SpaceFactory and NASA Kennedy Space Center’s “Swampworks” aims to advance lunar 3D print technology through testing in a vacuum chamber at temperature as low as -200°C. The 3D print material - a mix of regolith and biopolymer - is made from feedstock which can be produced locally on the Moon.

By 3D printing in a lunar-like environment, SpaceFactory and NASA have made significant strides in maturing our technology for a possible lunar surface demonstration within the decade. -

In January 2023, SpaceFactory launched our pilot robotic arm 3D printer, ASTRA. Building on the prototype developed for the NASA Centennial Challenge, SpaceFactory engineered ASTRA for scale, simplicity, and sustainability. ASTRA’s mission is to enable the next generation of builders and creators through its use of recycled 3D print materials, automated tool-path algorithms, and user-friendly interface.

Starting September 2023, SpaceFactory will launch a series of large format gantry-style 3D printers which leverage technology developed through our NASA partnership. Beginning with the T200 “Starforge”, these modular printers modular printers are designed to help a wide spectrum of industries in producing intricate parts, streamlining operations, and unlocking unparalleled efficiencies in their processes.